In a sports stadium, there are fewer high-traffic areas than the restroom facilities. Oklahoma State University’s historic stadium was built in 1913 so the restroom facilities had suffered a great deal of wear and tear from continued use over the years. So when the University planned to renovate and expand its stadium, it was an opportunity to upgrade the restrooms with new bathroom partitions that would add functional and aesthetic value, and endure the high volume of traffic.

In a sports stadium, there are fewer high-traffic areas than the restroom facilities. Oklahoma State University’s historic stadium was built in 1913 so the restroom facilities had suffered a great deal of wear and tear from continued use over the years. So when the University planned to renovate and expand its stadium, it was an opportunity to upgrade the restrooms with new bathroom partitions that would add functional and aesthetic value, and endure the high volume of traffic.

Hiny Hiders are made from premium, American-made one-inch thick solid HDPE. The solid plastic partitions resist dents, scratches, corrosion, bacteria, graffiti, and mildew, and unlike traditional metal partitions, they’ll never rust. With the number of partitions required in the installation it was a challenge to find the material that would last. Solid plastic will not break, and it never needs to be painted.

Hiny Hiders are made from premium, American-made one-inch thick solid HDPE. The solid plastic partitions resist dents, scratches, corrosion, bacteria, graffiti, and mildew, and unlike traditional metal partitions, they’ll never rust. With the number of partitions required in the installation it was a challenge to find the material that would last. Solid plastic will not break, and it never needs to be painted.

Hiny Hiders are available in a multitude of colors and textures however Reed took advantage of the product’s customization capabilities and specified the bathroom partitions be designed in the university’s school colors. In addition, to make the application even more unique, the door of each stall is personalized with the OSU logo.

More than 500 partitions were installed in the new stadium. Today, according to Donald Clark, facility manager, the Hiny Hiders partitions have proven to be low- maintenance. “Our metal stalls rusted, needed painting and graffiti was often a problem. Since the Hiny Hiders were installed we’ve had virtually no maintenance issues in any of the restroom stalls. The most we’ve had to do is wash them down with a garden hose.”

As Hiny Hiders are made with HDPE, they’ll have a long life cycle and be a cost-effective component to the new stadium. This is key in a stadium that has more than 40 restroom facilities. For OSU, such a large application, this is an enormous benefit.

Since the 2009 installation, the Hiny Hiders have endured the cheers and jeers of sports fans. “The bathroom partitions have really shown their durability while retaining their great looks,” said Clark. “Every hinge, every latch, every hanger works as well today as it did three years ago,” he said.

For Oklahoma State University, the plan to renovate the stadium was to transform a structure that was showing its age into a contemporary, state-of-the- art facility. The goal was to create unrivaled facilities for football players and fans alike. Boone Pickens Stadium can now be considered one of America’s top facilities from top to bottom.

In a sports stadium, there are fewer high-traffic areas than the restroom facilities. Oklahoma State University’s historic stadium was built in 1913 so the restroom facilities had suffered a great deal of wear and tear from continued use over the years. So when the University planned to renovate and expand its stadium, it was an opportunity to upgrade the restrooms with new bathroom partitions that would add functional and aesthetic value, and endure the high volume of traffic.

In a sports stadium, there are fewer high-traffic areas than the restroom facilities. Oklahoma State University’s historic stadium was built in 1913 so the restroom facilities had suffered a great deal of wear and tear from continued use over the years. So when the University planned to renovate and expand its stadium, it was an opportunity to upgrade the restrooms with new bathroom partitions that would add functional and aesthetic value, and endure the high volume of traffic. Constructed from premium, American-made solid HDPE with a homogenous color throughout, Scranton Products

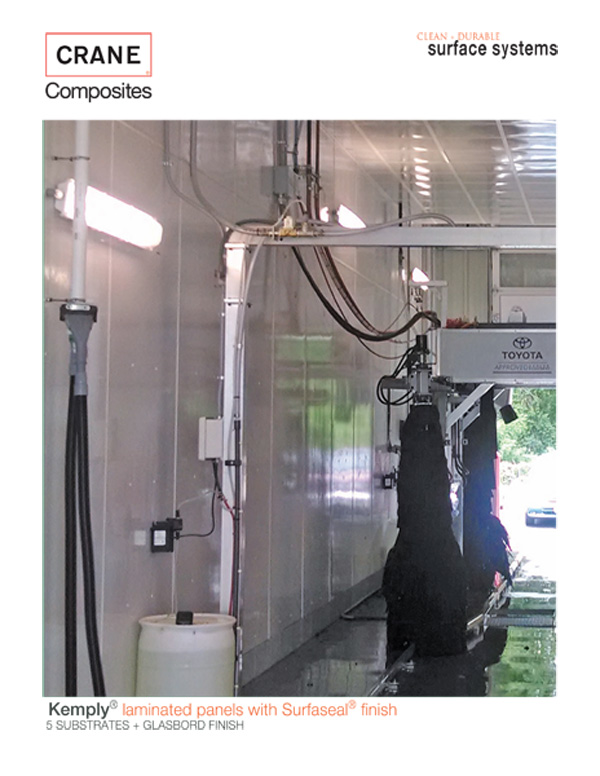

Constructed from premium, American-made solid HDPE with a homogenous color throughout, Scranton Products  For fiberglass reinforced plastic (FRP) wall and ceiling panels that combine unsurpassed hygiene and durability with high-performance and style, customers around the world trust Crane Composites. As the first and largest global manufacturer of FRP wall paneling, we offer the industry’s most innovative and resilient FRP panels.

For fiberglass reinforced plastic (FRP) wall and ceiling panels that combine unsurpassed hygiene and durability with high-performance and style, customers around the world trust Crane Composites. As the first and largest global manufacturer of FRP wall paneling, we offer the industry’s most innovative and resilient FRP panels.

Market segment: Food Industry

Market segment: Food Industry HDPE is naturally resistant to bacteria, odors, mold and mildew and the non-porous surface is very easy to clean. Graffiti wipes off easily with most non-abrasive cleaners and stickers and contact paper are easily removed. The lockers can also be power washed and steam cleaned without the worry of rust.

HDPE is naturally resistant to bacteria, odors, mold and mildew and the non-porous surface is very easy to clean. Graffiti wipes off easily with most non-abrasive cleaners and stickers and contact paper are easily removed. The lockers can also be power washed and steam cleaned without the worry of rust. For fiberglass reinforced plastic (FRP) wall and ceiling panels that combine unsurpassed hygiene and durability with high-performance and style, customers around the world trust Crane Composites. As the first and largest global manufacturer of FRP wall paneling, we offer the industry’s most innovative and resilient FRP panels.

For fiberglass reinforced plastic (FRP) wall and ceiling panels that combine unsurpassed hygiene and durability with high-performance and style, customers around the world trust Crane Composites. As the first and largest global manufacturer of FRP wall paneling, we offer the industry’s most innovative and resilient FRP panels.